Auditory Selectivity

Abstract

Auditory selectivity (A.S) is a tangible artwork that increases one’s umwelt of sounds in their environment, which they fail to perceive due to the brain filtering background information. Through the interaction with this artifact, one will be able to experience the difficulty of filtering information. They will have the ability to use a mallet and hit the different sides of the octahedron, which is a metaphor for the brain selecting what is important. Without hitting anything, they will experience the frustration from the overwhelming background sounds being portrayed by sound and lights.

Our Exploration as a Team (Three People)

- Concept driven design

- Ideation through prototypes and sketches

- Experience prototyping and user testing

- Object oriented programming for the Arduino

- Working with affordance

- Top quality final prototype

- Short video

- ACM research paper

My Tasks

First Step

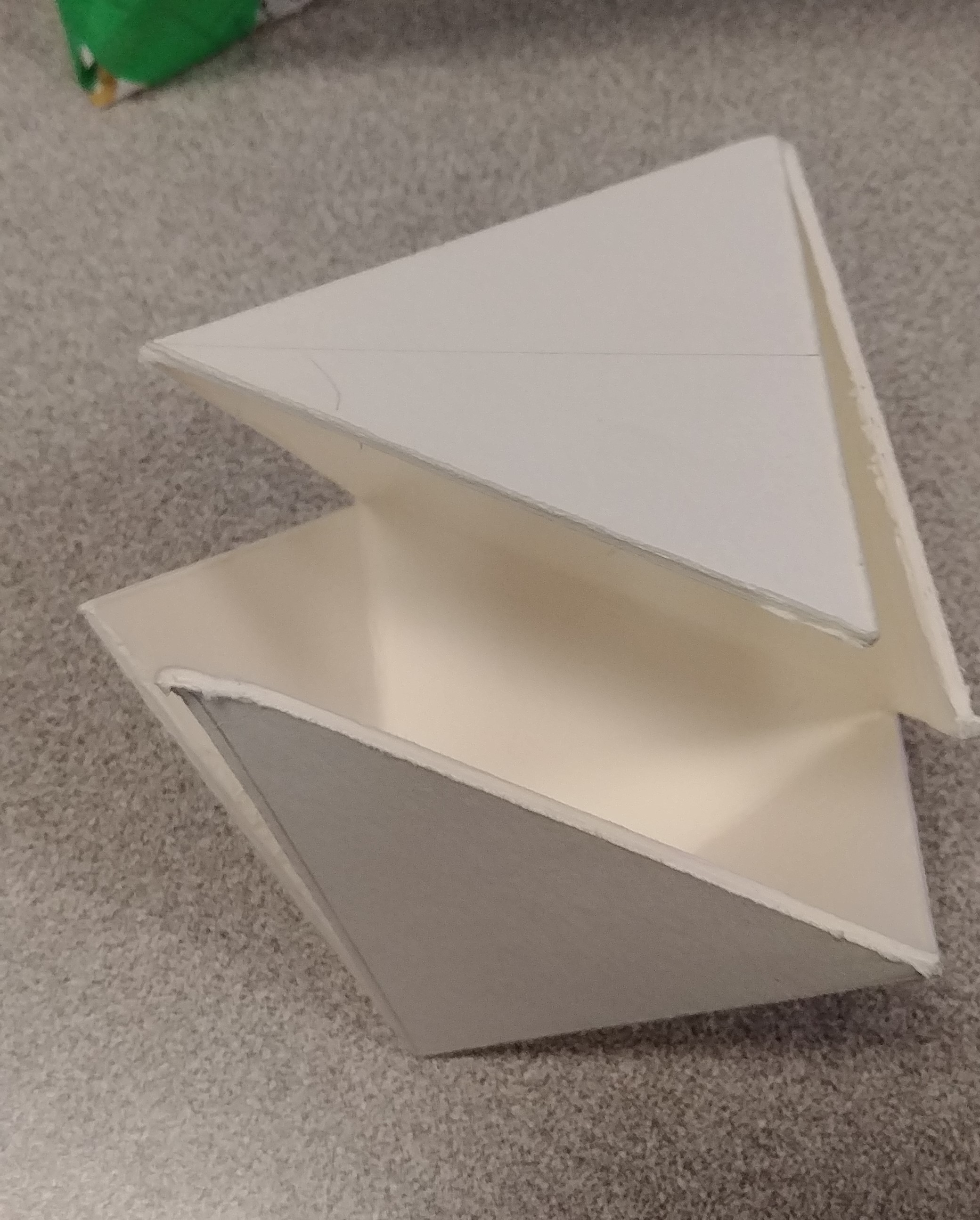

One material that I have explored was card stock paper, a very hard and flat cardboard paper that can be cut. By folding this paper, I was able to achieve an octahedron shaped volume easily. Considering that we have decided that the sides should be see through, I could have cut out the sides leaving a small frame and gluing a transparent sheet of a material, which I will cover later on in the report. However, the problem with this method of construction is that since the octahedron will be really big, it is necessary for us to purchase a large sheet of cardstock which will be extremely expensive. In addition, cardstock is extremely heavy which will result in a heavy artifact. Most importantly, considering that our project will be used in different environments such as parks during different weathers including rain or snow, a cardstock artifact will simply be soaked in water and lose its form and break.

Second Step

I know that thick wooden dowels are extremely strong so I was thinking of creating a structure with them. I have worked with wooden dowels prior to this project so I know it is possible. First, I needed to figure out what the structure will look like so I have assembled a quick prototype with paper and spaghetti. Spaghetti is frequently used in seismic testing in place of wood since they have similar properties (ability to withstand torsion, tension, shear and so on); hence, it will be an easy, cheap, and accurate substitute for wood.

After the spaghetti prototype was constructed, I knew that this will work for wood so I found the dihedral angles of the octahedron and calculated the angles of each side. In addition, we limited the length of each edge to 24cm because the largest internal component, being the phone with the OCG cable attached can fit inside and we wanted the final prototype to be as small as possible with since it will be carried to different locations. Once that was decided, I began cut the wooden dowels with loppers since hand saws do not work well and sanded them to angle. Then I began to glue sides together on a cardstock mold which I have made.

Third Step

Unfortunately, the glue was not strong enough so I had to look for other options. In order to ensure that the wooden frame is extremely strong, strong enough for a child to use as a seat, I have drilled small 3/32-inch holes, the second smallest drill bit that can be purchased since the smallest drill bit is know to snap. Then, I have connected it with a metal wire. I have tightened the metal wires enough so the wooden dowels will not slide; however, I have not tightened the wires to max tightness because that may shatter the wood and increase the force of tension and shear at the joints when hit by the mallet. By reducing the tightness slightly, I have created a bit of a wiggle room so force can be dispersed from the joints to the other parts of the wooden frame. This will prevent the wooden frame from shattering upon impact. In addition, this will also allow wood to expand and contract as temperature and moisture changes, similar to the idea that bridges have spacers. I was inspired by the fasteners on cables of the bridge, so for the two ends of the octahedron, I have used a similar design for the spaces. These spaces locks and connects the four wooden dowels in a sturdy manner so they will not slide.

Fourth Step

Inside the frame, I have also installed a few connectors which will relieve stress from the joints which further strengthens the overall prototype. The X shaped connect is perfect for a surface to be built on to which will contain the internal components such as the phone or the Arduino board.

Fifth Step

The last component to this prototype was the side panels. Considering that we wanted a translucent material that is flexible and hard, but is able to be cut without special machines, we have chosen this particular plastic cutting board. This is also extremely cheap which is one of our constraints. Its beautiful matt surface on one side provides a translucent layer so that light from the inside will look dispersed rather than focused and bright. In addition, this material has the front side glossy (backside is matt), so light from inside the prototype will reflect off the sheets slightly so give it an overall shining affect, reducing the potency from one side, yet it will still be clear which side is the intended side to be lit.

Once this was done, I needed a way for the plastic sides to connect onto the wooden frame so that they can be detached for internal components to placed inside. Initially, I was thinking of adding small screw which can be screwed on and screwed off. The screw was quite expensive and each time they are screwed in, it damages the wooden frame. The only possible solution that I have thought of was using Velcro or snap fasteners. Snap fasteners were small so they require screw to attach. Velcro on the other hand can be glued on with super glue as the adhesive surface it came with was not strong enough. However, the glue is not extremely tight and will loosen through multiple disassemblies. Nonetheless, this doesn’t matter because the end use will not be taking it apart. As long as the plastic sides are attached sturdily to withhold the force of the mallet, it will suffice. Therefore, Velcro is an excellent idea.

Our Tasks

Sixth Step

Our final prototype used We used capacitance touch sensors as the input source which detects when the strike of the mallet. Once detected, it will notify the Arduino Mega which will then activate the actuators being the RGB LED and the phone speaker which was connected through the OTG cables. The phone will also provide power for the Arduino.

Last Step

After user testing, will be explained in the research paper below, we presented our work. Our tangible artwork, Auditory Selectivity allows users to experience the process of the brain filtering ambient sounds in their surroundings. Through this process, they will understand the importance of filtering and how difficult the process is. By striking the sides of the octahedron artifact with mallets, being a metaphor for the brain to filter information, they will realize that the side that they hit may not always be the side that is focussed, but additional sides may also be focussed. This project will also allow the users to experience what people with ADHD faces with their limited attention spans. Similar to how the mallet may not always select the sides that is struck, people with ADHD will also have difficulty focusing on specific tasks. The time given to complete this project limits us to fully incorporate the features we had in mind, moving forward, we could change the ambient sounds dependant on the environment the tangible object is located in.

Discussions

Following the extensive research on similar projects, what struck us as interesting in regards to our system, is that Auditory Selectivity is first in its kind to combine the concept of cognitive filtering to a tangible auditory device. We believe the strength lies with the structure and assembly of our tangible object in which it easily affords user interaction, and is easily transportable.

Auditory Selectivity allows the users to experience the task of filtering information done by the brain and it allows them to understand that this process is not as straightforward as they may have imagined. It also allows them to understand how much information is being filtered and what they are aware of only a tiny fraction of the information in their surroundings. By having the demo mode playing lots of noises, this makes the user feel uncomfortable or overwhelmed which promotes their interaction with our tangible artwork.